Application areas

One of the main tasks of strategic PuT planning is to determine the number of vehicles, which are required to run a predefined timetable. The accumulated costs are thus to be minimized. To solve this task use the line blocking procedure in Visum.

Another task of strategic planning is, planning the vehicle use dependant on the capacity of the individual vehicle combinations and the demand on vehicle journey level. To do so, the line blocking procedure with vehicle interchange can be used.

If Visum is applied within an overall context of a PuT operating line costing and revenue calculation, the line blocking results can then provide a cost model module. With the vehicle demand, line blocking provides an input parameter for determining the vehicle type dependent costs, more precisely, the vehicle demand flows into the attribute Cost Vehicle. Furthermore, line blocking also determines the required empty trips. The empty time thus flows into the attribute Cost Time, the empty kilometers into the attribute Cost Distance. An overview on the PuT cost and revenue model can be found in Illustration 212.

|

Note: In the directory C:\Users\Public\Documents\PTV Vision\PTV Visum 2024/Examples, you can find an example of use on this topic. The PuT eLine Blocking example shows the use of line blocking for a given public transport supply considering battery electric vehicles. |

Basic terms

The basis of the line blocking efforts is the timetable with the vehicle journeys, which are to be run by the blocks (Visum creates the blocks on the level of vehicle journey sections). Blocks are created by linking individual trips to trip chains, which can each be serviced by a vehicle combination. In the simplest case, a vehicle journey is concatenated at its last stop with a subsequent service which starts at the same stop. If such a linkage is not possible nor useful, an Empty Trip can transfer the vehicle combination to another stop point. Only the empty trips with a real change of location between two stop points count as interlining. If a vehicle changes from one stop point to the depot, at the same stop point or vice versa, this is referred to as pull-in or pull-out. This difference is important when selecting the option Interlining permissible (User Manual: Parameters of the line blocking procedure). For pull-in or pull-out without change of location, neither empty trips nor empty kilometers accumulate.

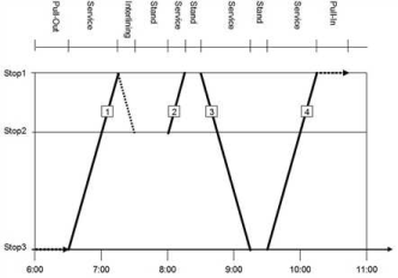

As displayed in the Illustration 185, the following times are included.

- Interlining times

Time required for interlining trips between two vehicle journeys which end/start at different stop points.

- Layovers

Layover time at a stop until next vehicle journey departure time.

In Visum, those unproductive empty times without passenger transport can be calculated by means of the line blocking calculation and will then be considered during cost calculation for lines. The same applies to empty kilometers or empty miles.

Once line blocking has been calculated, the empty times and empty kilometers/miles of each line block are known and can be displayed in the Line Blocks list.

Illustration 185: Example line block with pull-out trip, interlining trip and pull-in trip

|

No. |

Action |

FromStop |

ToStop |

Dep |

Arr |

Line |

Time |

Length |

|

1 |

Pull-Out |

|

Stop3 |

06:00 |

06:30 |

|

30 min |

10 km |

|

2 |

Vehicle journey |

Stop3 |

Stop1 |

6:30 AM |

7:15 AM |

BUS1-1> |

45 min |

30 km |

|

3 |

Interlining |

Stop1 |

Stop2 |

7:15 AM |

7:30 AM |

|

15 min |

10 km |

|

4 |

Layover |

Stop2 |

Stop2 |

7:30 AM |

8:00 AM |

|

30 min |

0 km |

|

5 |

Vehicle journey |

Stop2 |

Stop1 |

8:00 AM |

8:15 AM |

BUS1-2> |

15 min |

10 km |

|

6 |

Layover |

Stop1 |

Stop1 |

8:15 AM |

8:30 AM |

|

15 min |

0 km |

|

7 |

Vehicle journey |

Stop1 |

Stop3 |

8:30 AM |

9:15 AM |

BUS1-1> |

45 min |

30 km |

|

8 |

Layover |

Stop3 |

Stop3 |

9:15 AM |

9:30 AM |

|

15 min |

0 km |

|

9 |

Vehicle journey |

Stop3 |

Stop1 |

9:30 AM |

10:15 AM |

BUS1-1> |

45 min |

30 km |

|

10 |

Pull-In |

Stop1 |

|

10:15 AM |

10:45 AM |

|

30 min |

10 km |

Table 211: Example line block with pull-out trip, interlining trip and pull-in trip

Optimization problem

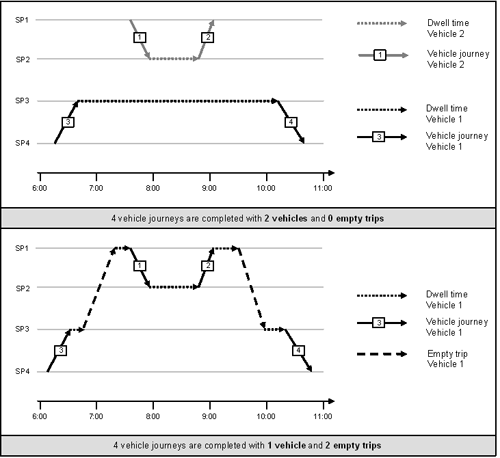

For the optimization task of line blocking, there is always a conflict between the number of empty trips (or more so the sum of empty kilometers covered on the empty trips) and the number of vehicles to be used. By creating empty trips, the number of required vehicles can usually be reduced, however, costs accumulate for the additional empty trips (Illustration 186 bottom). On the other hand, empty trips can be saved when implementing more vehicles (Illustration 186 top). Depending on how costs are assessed by the user regarding empty trips on the one hand and additional vehicles on the other side, line blocking can return various optimum solutions. In addition to these two basic parameters, Visum offers more indicators which can be integrated into the cost function. The detailed cost function which is minimized in this context can be found in the line blocking procedure description (Construction of the graph). The solution principle of line blocking in Visum, which includes creating a graph and the solution as a flow problem, is also described here.

Illustration 186: Conflict between empty trips and vehicle demand

Line blocking evaluation

The line blocking model and line blocking procedure allow you to analyze complex problems regarding line blocks and the resulting number of vehicles required. In the following section, the advantages of the line blocking procedure are evaluated.

- The solution as a graph flow problem now makes it possible to include long-lasting downtimes of vehicle combinations – for example in depots - in the process. There is no maximum dwell time, as a vehicle is permitted to stay in the depot or anywhere else for any desired period. The dwell time can now be evaluated by a cost rate freely defined by the user and can thus be included in the objective function of the optimization problem (Construction of the graph).

- The estimate of the number of vehicles required to run the blocks is more precise.

- If closed blocks are created, the empty trips can be determined which are required to return those vehicles shifted from one location to another, to their starting point. The non-consideration of the time required to return the vehicles would lead to an underestimation of the empty kilometers and empty times.

- The duration of blocks is limited by the assignment period that can be one or several calendar days. This allows the program to calculate the correct number of vehicles.

- Minimum layover times have a major impact on possible transfers. As common in practice, you may use minimum layover times to interpret the restrictions during the assignment period as soft. You can thus balance the effects of minimum layover time and vehicle deployment.

- Blocks can be reedited manually. For that purpose, you can also create user-defined block item types. This is how you can manually include maintenance tasks or washing cars in block planning, for example.

- You can change various parameters per block version in order to easily compare several line blocking scenarios.

- At any time, a line block is consistent with its vehicle journey sections. Possible inconsistency only applies to reduced pre and post preparation times or empty trips in the case of changes to the network after line blocking.

- Blocks are only subject to the demand of correctness when they are being used, they do not necessarily have to be free of errors. This means: In many cases, you can edit the basic network whereupon existing line blocks are not discarded. Only when evaluating them in other procedures, line blocks have to be free of errors - for example as a basis for vehicle requirement, empty kilometers and empty trips computation for the calculation of vehicle-dependent costs by means of the PuT operating indicators procedure (Illustration 212). Check line block (Line block check) thus helps finding and correcting potential errors.

- Several additional issues may be considered during line blocking. This includes the intended duration of the line blocks (number of blocking days), distribution of the layover times, scheduling of repeated stationary events (maintenance) and the consideration of the direction of travel.